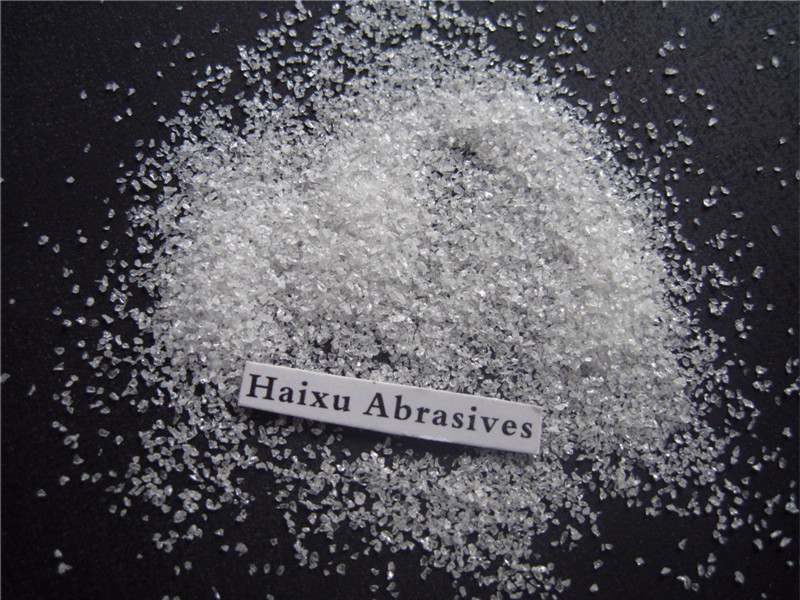

What is white fused aluminum oxide?

White fused aluminum oxide is made of industrial aluminum oxide as raw material, refined and crystallized by electric melting. It has a slightly higher hardness than brown fused aluminum oxide and slightly lower toughness. It has high purity, good self-sharpening, strong grinding ability, low heat generation, high efficiency, acid and alkali corrosion resistance, and good high temperature thermal stability.

1. Chemical composition and physical properties

Chemical composition: The main component is aluminum oxide (content ≥99%), containing trace impurities such as iron oxide and silicon oxide, and is white granules and powder.

Hardness: Mohs hardness reaches 9.0, second only to diamond.

2. Production particle size

FEPA: F12 F14 F16 F20 F22 F24 F30 F36 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000

JIS: #240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000 #2500 #3000 #4000 #6000 #8000 #10000

3. Production process

White fused aluminum oxide is prepared by high-temperature smelting process:

Raw material processing: Industrial aluminum oxide is used as raw material, and is pre-treated by crushing and screening.

High-temperature smelting: After melting at a high temperature of more than 2000℃ in an electric arc furnace, it is cooled and crystallized.

Post-processing: After cooling, white fused aluminum oxide grit is crushed, magnetically separated, iron removed, screened, and other processes to make products of different particle sizes; white fused aluminum oxide micropowder is made through acid washing, overflow classification, drying, and screening.

4. Core characteristics

Physical characteristics: dense texture, most particles are sharp or spherical, clean surface, easy to combine with binder.

Chemical characteristics: high chemical stability, acid and alkali corrosion resistance, stable performance at high temperature.

Functional characteristics: strong self-sharpening (automatically sharpened during grinding), long wear life.

5. Application fields

Due to its performance advantages, white fused aluminum oxide is mainly used in the following scenarios:

Abrasives and grinding tools: manufacturing grinding wheels, sandpaper and other grinding tools for polishing and sandblasting of metal/non-metallic materials, etc.

Precision manufacturing: ceramic bond grinding tools, precision casting (such as precision casting model lining).

Coating : floor coatings, powder coatings, UV coatings, etc.

Refractory materials: high-temperature kiln linings, refractory bricks, etc.

Emerging fields: aerospace parts, high-precision tool manufacturing, etc.

6. Advantages and development prospects

Advantages: high hardness, impact resistance, environmental protection (recyclable).

Challenges: high raw material costs and high energy consumption in the production process.

Prospects: With the upgrading of manufacturing industry and the development of emerging industries (such as new energy and biomedicine), the demand for white fused aluminum oxide in the fields of high-precision processing and special materials will continue to grow.

7. Market Supply

Zhengzhou Haixu Abrasive Co., Ltd. is a major manufacturer of white fused aluminum oxide, providing various types of white fused aluminum oxide grits and white fused aluminum oxide mircopowder, with sufficient inventory and support for export-grade customization. Its regular packaging is 25 kg plastic woven bag + ton bag/pallet wrapping.