Kinds,applications and manufacturing process of emery sand

Emery sands are a type of material with high wear resistance, commonly used in various industries and manufacturing processes to improve surface hardness and durability. The main types, uses and processes of emery sands are as follows:

Main kinds

First: Artificial emery sand, mainly including white fused alumina emery sands, brown fused alumina emery sands, black carborundum emery sands and green carborundum emery sands

White fused alumina emery sands, the main component of which is alumina, accounting for more than 99.5%, are formed by melting alumina in an electric arc furnace and recrystallizing it. The Mohs hardness is 9.0, which is slightly higher than that of brown fused alumina emery sands, but lower than that of carborundum emery sands.

Brown fused alumina emery sands, whose raw material is bauxite, are also formed by melting and recrystallizing. The Mohs hardness is slightly lower than that of white fused alumina emery sands, close to 9.0, but its toughness is slightly higher than that of white fused alumina emery sands.

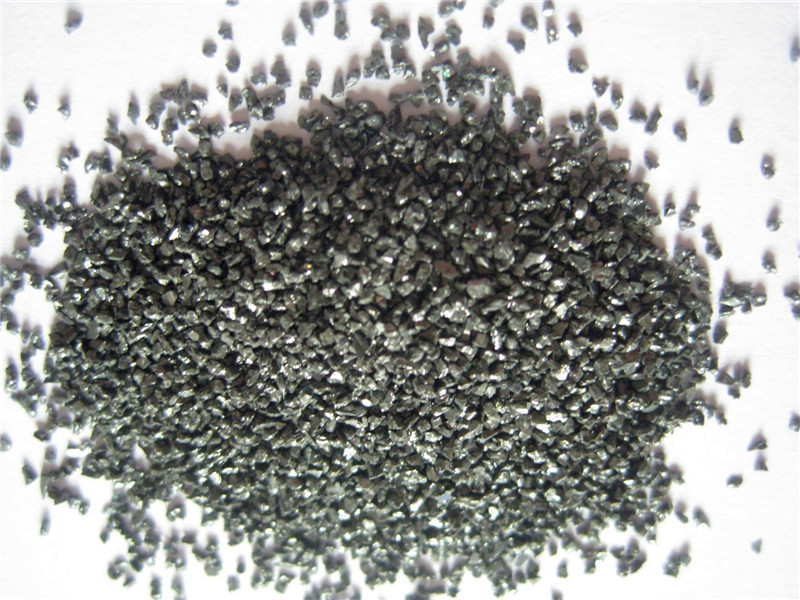

Black carborundum emery sand: This emery sand is mainly made of black carborundum, black in color, with higher mechanical strength than fused alumina, brittle and sharp. It is often used for pipe wear-resistant layer, aircraft engine wear-resistant layer, diamond tools, water grinding discs, dry grinding disc production auxiliary materials, precision tool grinding and polishing, high-hardness steel tool grinding, etc. .

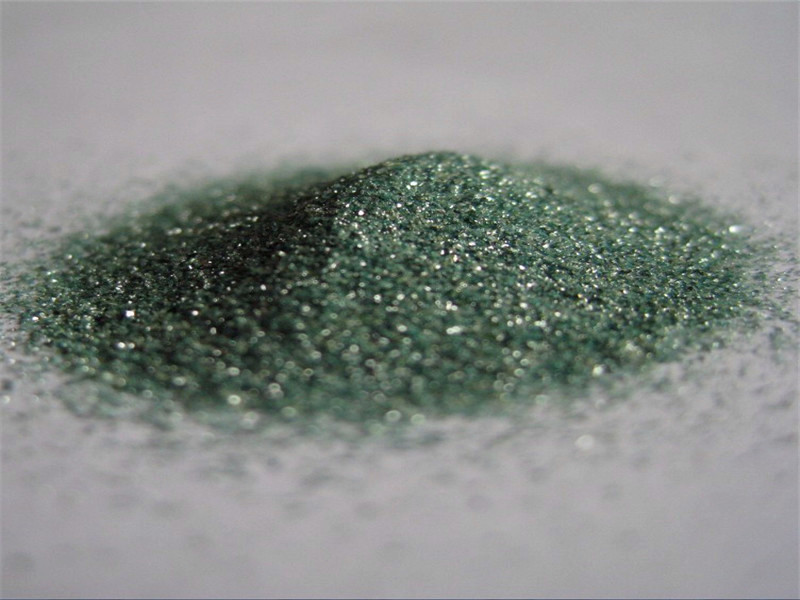

Green carborundum emery sand is made of quartz sand, petroleum coke (or coal coke), sawdust (salt is needed when producing green carborundum) and other raw materials through high-temperature smelting in a resistance furnace. It has high strength, high hardness, wear resistance, corrosion resistance, oxidation resistance, high thermal conductivity, good high-temperature stability, corrosion resistance, etc.

Second: Natural emery sand: Also known as garnet sand, it is an abrasive material made of silicate minerals through hydraulic sorting, mechanical processing, screening and grading. It is mainly used in the manufacture of wear-resistant flooring.

Main applications

Industrial applications: emery sand is widely used in various industrial manufacturing processes, such as pipe wear-resistant layer, aircraft engine wear-resistant layer, diamond tools, water-abrasive discs, dry-abrasive disc production auxiliary materials, etc.

Precision machining: It is widely used in precision tool grinding and polishing, high-hardness steel tool grinding, single-sided and double-sided grinding machine grinding powder, etc.

Ceramic and metal processing: used for functional ceramics, functional ceramic stone, honeycomb ceramic building ceramics, high-hardness silicon wafer cutting, quartz cutting, wire cutting, etc.

Other applications: emery sand is also used for raw materials for production such as oilstone, grinding stone, whetstone, brush roller, optical glass stone polishing wheel, marble polishing, gemstone polishing, etc.

Manufacturing process

The manufacturing process of emery sand usually includes methods such as hydraulic sorting, mechanical processing and screening and grading. For example, natural corundum is extracted and processed from silicate minerals by these methods.

In summary, Emery sand plays an important role in industry and manufacturing processes due to its high wear resistance and multiple uses.